Water Use and Treatment

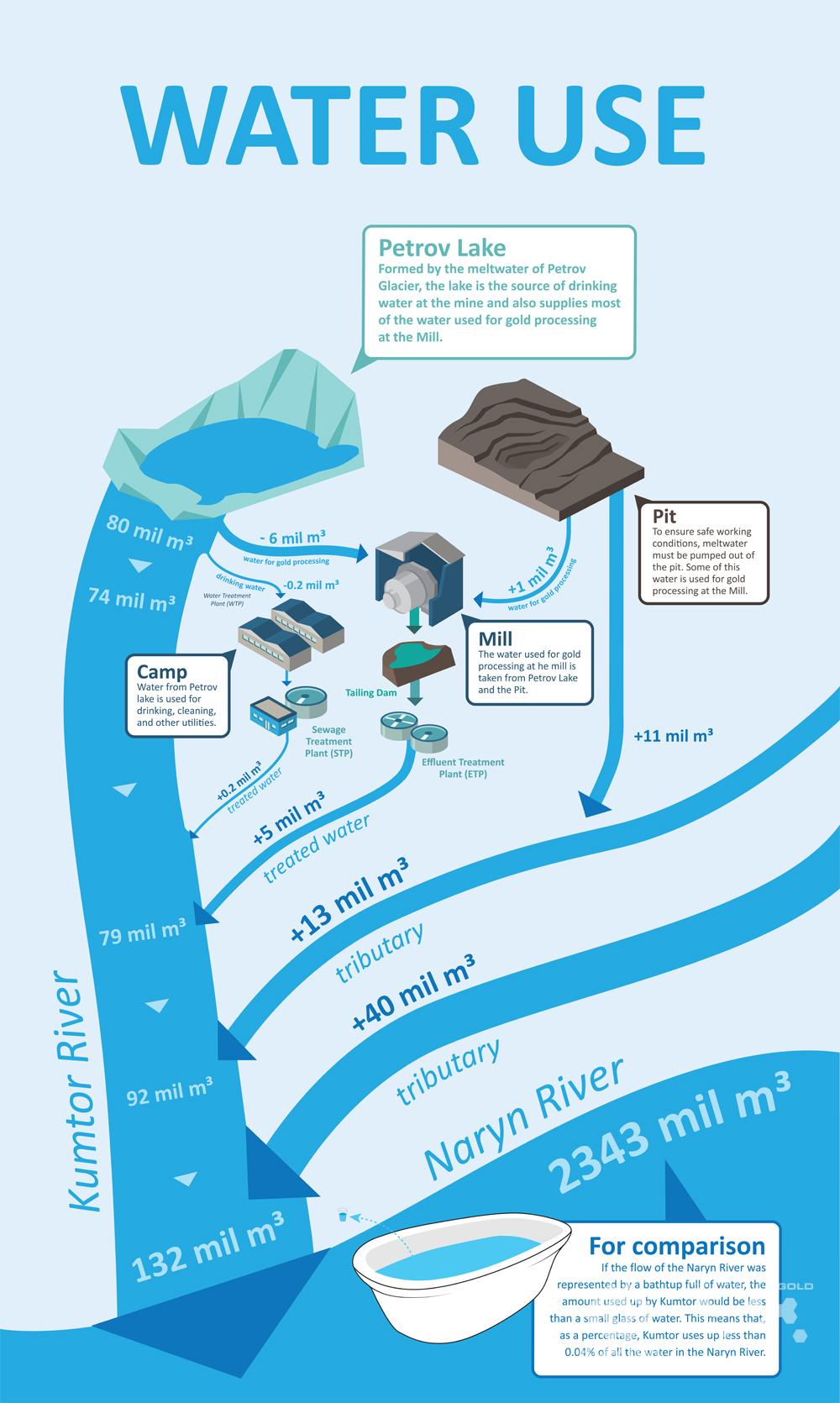

Kumtor’s water intake is about 7% of natural throughflow of Petrov glacial lake

Kumtor treats its industrial and domestic effluents to meet prescribed standards prior to discharge

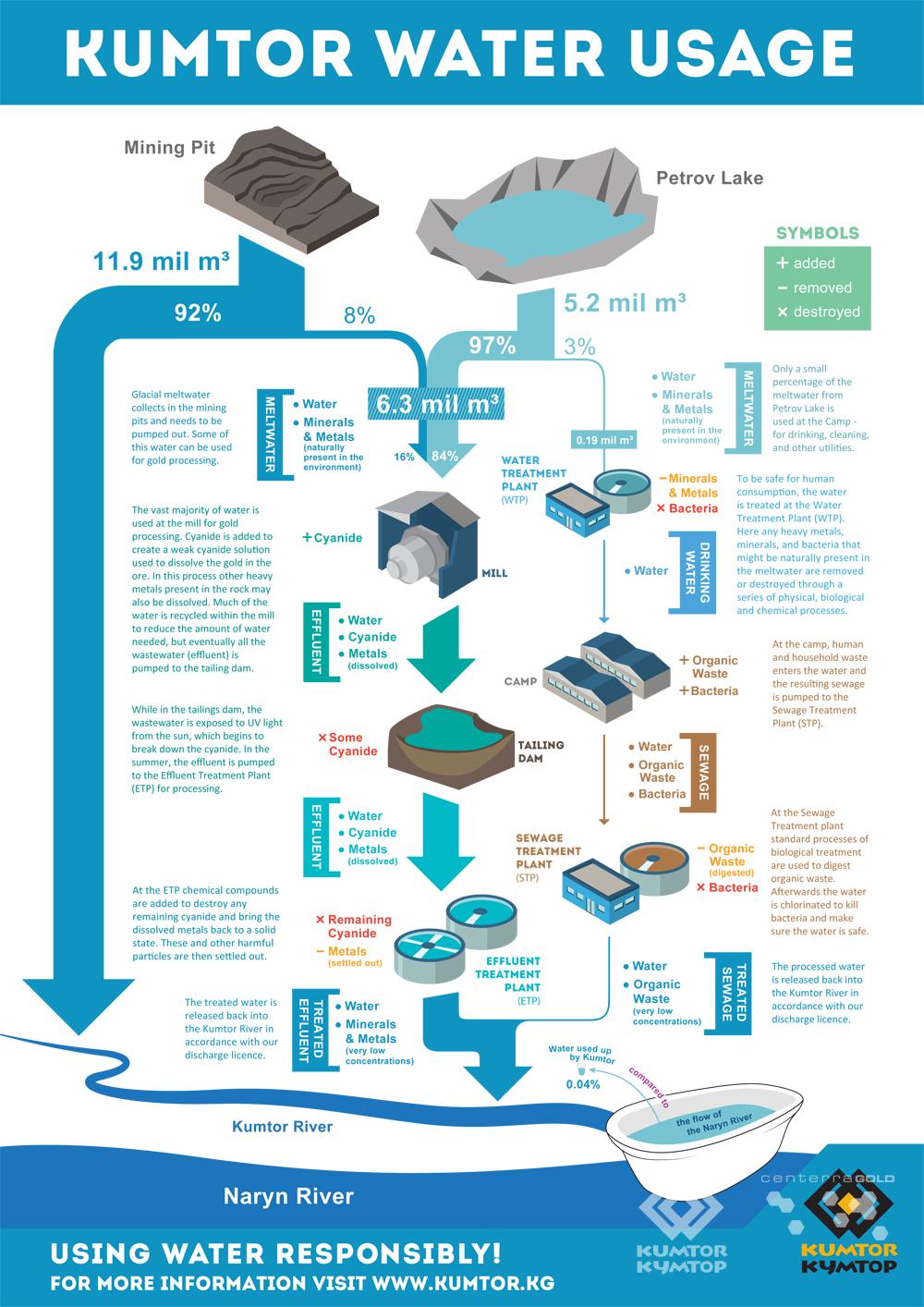

Water use

We use water for operational activities, mostly in the mill, and for domestic use (drinking and sanitary) in the mining camp, offices, and workshops.

Our main water management responsibilities are:

- Providing safe drinking water for our employees

- Removing water and ice from the open pit to ensure access to ore, and stable and safe working conditions

- Ensuring water returned to the natural environment is safe and meets defined quality criteria

- Managing run-off to reduce sediment load entering surface water

Most of the water we use is collected from Petrov Lake. We must also pump large volumes of water from the open mine pit to maintain stable and safe working conditions, some of which we use at the mill, thus reducing our demand from the lake. Our main use of water is as process water in the mill, for crushing the ore and processing it to produce gold.

Water treatment

Petrov Lake has naturally high concentrations of sediments, giving the lake a characteristic milky appearance, along with elevated background concentrations of some parameters such as iron, aluminium, and suspended solids.

Process water does not require treatment beyond settlement of sediments. However, the water quality of Petrov Lake does not meet hygienic drinking water standards without treatment. To generate drinking water, we apply treatment methods standard for public supplies around the world. These include flocculation, filtration, chlorination, and ultra-violet treatment. In combination, these processes remove fine sediments (which may carry metals) and disinfect the water for safe storage and use.

We have two systems to treat wastewater before safe discharge to the environment. Sanitary wastewater is treated at the sewage treatment plant (STP). This uses standard processes of biological treatment and chlorination.

Industrial wastewater containing residual cyanide is a component of tailings slurry discharged by gravity flow from the mill to the tailings management facility (TMF). The liquid component of tailings, approximately 51 percent of the slurry, is pumped to, and treated in compliance with established standards, at the effluent treatment plant (ETP) before being safely discharged to Kumtor River. Due to the freezing winter conditions, the treatment and discharge of wastewater is restricted to the warmer season, mainly June to November.

We are improving our management of run-off from snow and ice melt. As much as possible, we divert clean meltwater from Davidov and Sarytor glaciers away from waste rock dumps, and into the Kichi Sary-Tor stream. We also constructed a number of settlement ponds along Lysyi valley to collect large sediment particles.***